The CIY is becoming Reality

A father son team builds CIY #1 in Duluth, MN.

The last update had me quarter scale modeling the CIY hull. That work has completed and I've even put some paint on the model so it looks presentable. The model is also a great opportunity to use up left over paint and to test colors. I consider the color scheme -- and lack of varnish I might add -- to be an important part of the overall feel of my boats. I am not settled on the scheme, but still looking for the right brown for gunwales. I like the sand interior. The dark blue is the only boat I have ever used it and it works OK, but I am not in love with it.

|

| My little guy helped me paint the interior of the CIY model. He said the interior color "looks really good, Daddy". So I'll go with that! |

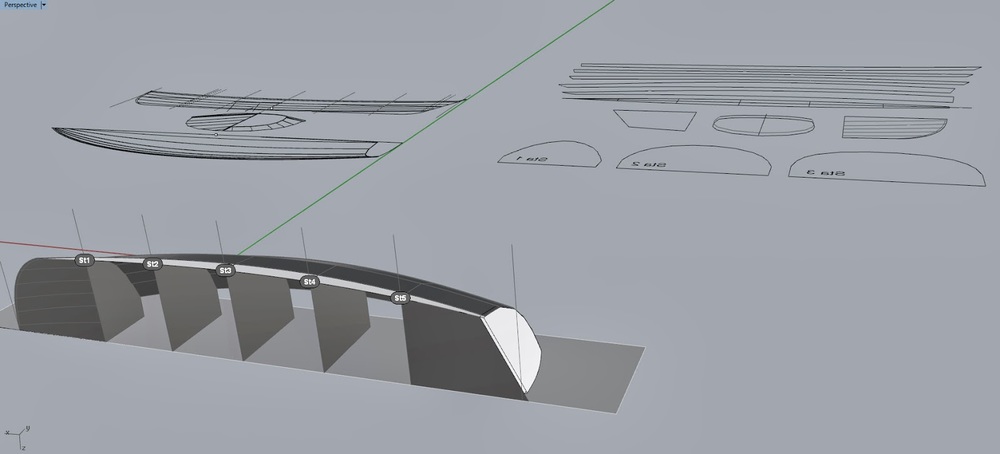

CNC Cutting in Maine

The parts for the kit were cut at Hewes & Co in Blue Hill, Maine. They also cut the Vivier boats now and all the Oughtred kits and I am so glad to be doing business with them. Here is their work:

|

| The CNC cut Advantech chipboard supports for bulkheads with some patterns, too. |

|

The CIY planks being CNC cut with the NC Scarf.

|

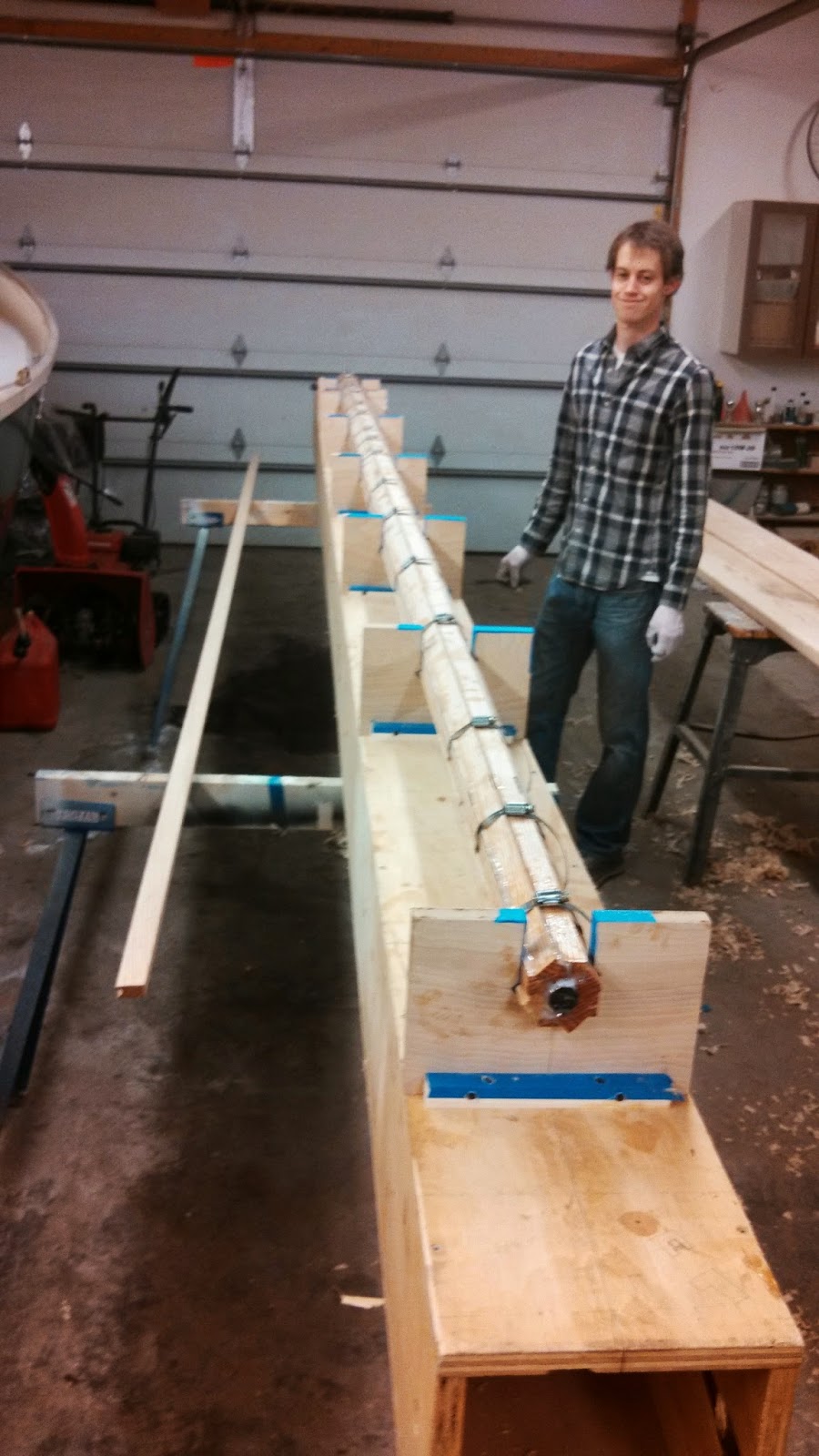

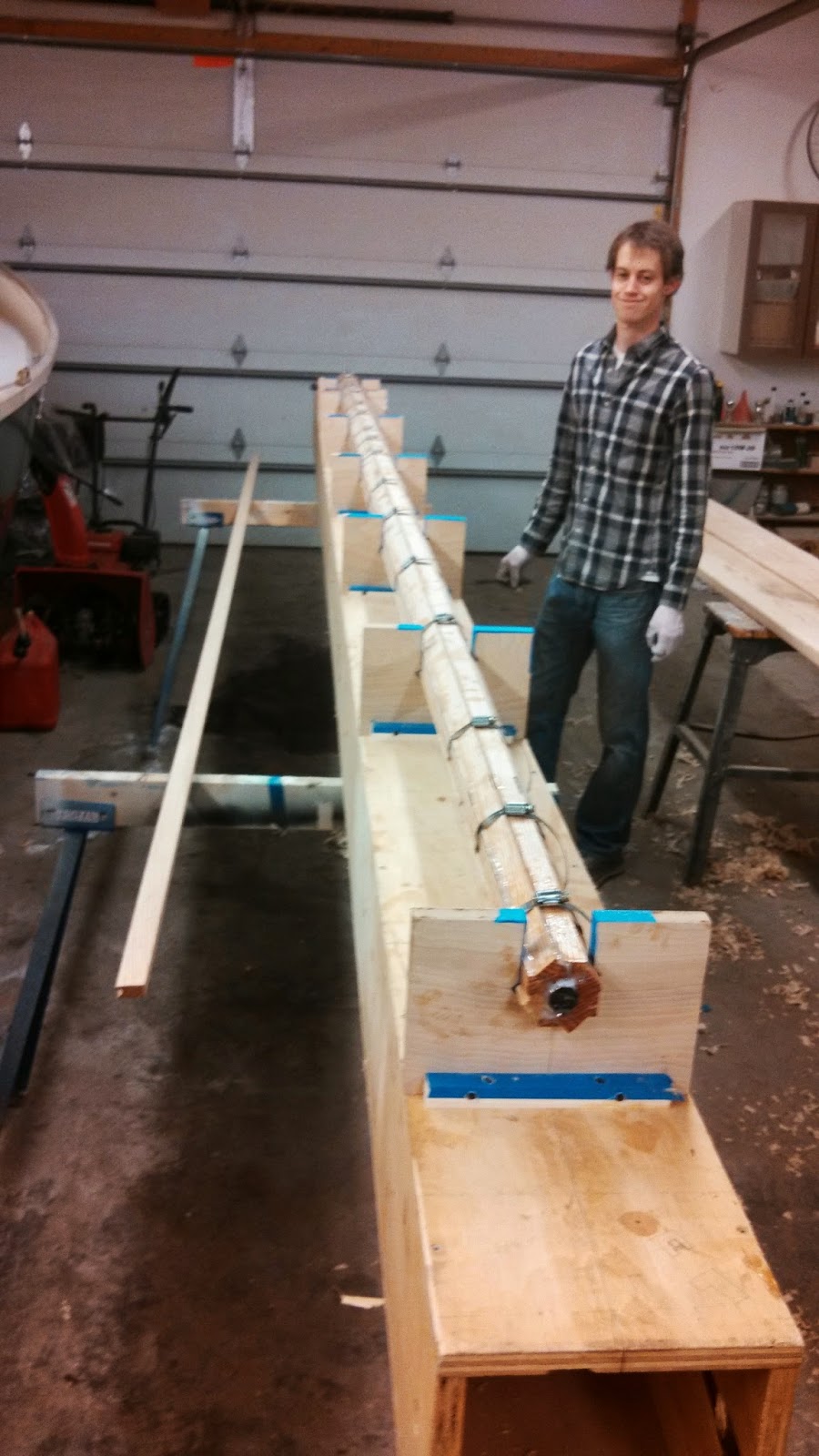

While the cutting was going on in Maine, the builders in Duluth were starting the birdsmouth masts and spars. They are great, hard working guys and have built several boats.

|

CIY Builders fabricating hollow-birdsmouth mast.

|

|

The kit arrives in snowy Minnesota. You can see the Advantech strongback components here.

|

|

| The parts making begins. Here they glue up the NC stem. |

My way of giving

In the meantime, in my studio overlooking the Saco River I work on more CAD files for people who want to build my boats. It is the highest honor and I will work hard to make it happen for them. They always give back and make the design better than I could have made it alone. The revised KDI kit is about to be cut again on the West coast, the new Drake 19 is shaping up for a few interested rowers, and the Deblois Street Dory is getting a revision based on the Compass Project build and plans and kits will be sent out this spring. I have views like this to keep me going.

|

| I live in the North Dam Mill there on the left bank if the Saco River. The ice is almost out on the river! |