Rowing the San Juan Islands in the Drake Rowboat

KDI Design Project

Design Projects

Sponsorship and Commission Opportunities

2015-16

A new approach to getting projects funded and delivered is through a model sort of like crowdfunding. A design project is any boat design that is either started from scratch or a project where an existing design (that has been built) is reworked or it may be a boat that has been design but not built which needs further development.

The KDI has been crowdfunded for this Fall...a number of sponsors pay into the project and receive the plans for free and a discounted kit. I benefit from having paying work, We all benefit by having the work get done!

|

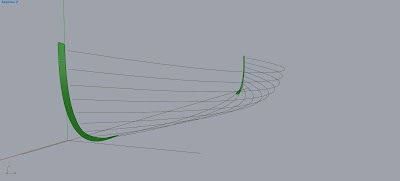

| The hull lines for the new KDI sketched out. |

Another design project is the Drake Raceboat. It has never been built, but needs sponsorship or a commission to finish the speculative work that I have started...a 3D hull model. Further work to do is to build a hull model, finish designing the interior, create cutting files and draft the plans. The Drake Race is all about speed and efficiency but retains the seaworthy faering-esque hull.

|

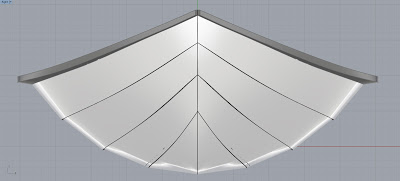

| The Drake Raceboat has been modeled in the computer but that is it until sponsorship comes along. |

Another design project is the Caravelle Skiff. It has been built a few times now, but soon a sailing model will be launched and from those sea trials a set of revisions will me made (I will call it a mk2 model) and the plans and kits will be delivered to those who preorder kits. I am looking for a few more preorders. A gent in NYC will cartop his skiff to all sorts of places around LI Sound for sailing and rowing.

Lastly, an example of a scratch design project is my brief detailing what I will likely call the Calendar Daysailer, which is actually the precursor for the sail-and-oar boat the Calendar Islands Yawl. This new boat model will be 90% daysailer with water ballast and a motor well and a lot of space for 4 people to go out sailing.

Contact me at boatkits@gmail.com

A Real Hull Model

The Calendar Iands Yawl

Hull Modeling in the flesh: part 1

CNC cutting parts for a quarter scale model

|

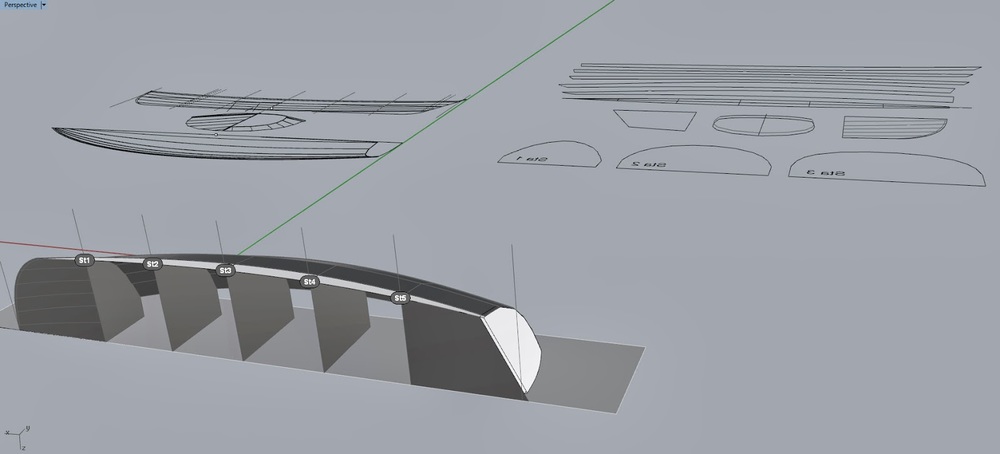

| The 3D computer model is sliced up into sections that become molds for defining the hull shape. |

|

| You can see the molds formed now, trimmed to the hull surface, and one more to go! |

|

| The hull is planked and ready to be broken up into the "flat" 2D geometry. |

|

| A neat screenshot that shows the 3D and 2D nature of the work: in the foreground is the 3D hull model. In the background is the geometry flattened onto the "construction plane". |

|

| This is the file with the 2D geometry as received by the CNC cutter, CNC Routing & Design in Camden, Maine. Tim will load the file into his Shopbot software, make toolpaths, and cut the parts. |

|

| The ShopBot machine cuts to my lines with a couple thousands of an inch accuracy. These are the planks of the boat, the bottom keel plank in the center and the sheer strake to the far right and left. |

|

| The molds of my quarter scale kit around which the planks will be wrapped and checked for fairness and for fit. |

A Deblois Street Dory

to The Compass Project in Portland, Me is building a DSD with a group of kids and they are doing a great job.

The boat is built like dories have always been built, using the bottom to erect stem, frames, and transom, then turning over the boat upside down on a strongback. Everything is plumbed and braced then planking begins.

Here the garboard has been installed and the sheer clamp is being fit. This is the only departure from traditional dory construction, the incorporating of the clamp helps tie together the frames into plumb and lock in the ends of the boat. It is a bit of a 3D puzzle!