This is the most often asked question I get, besides “How tall are you?” or “Do you play basketball”? The answer to the former is 6’6” and the latter question may be answered with “No, do you play miniature golf?”

But seriously, this is a fair question. How are your boats built?…is really what folks are asking, but the assumption is often this: since it is a kit, it must be stitch-and-glue construction. No, that is not the case.

I didn’t like getting this question early on because I knew my boats were certainly not stitch-and-glue but I was still working out a lot of the construction methodology on the fly. What is interesting is that people were and still are very surprised when they see one of our beautiful boats and learn that it was a kit. They exclaim, “THAT is a kit boat!?” But the first question still was always…stitch-and-glue?

Family week, class of 2021 - unfortunately I snapped this after the family from CA already left

Our boats are primarily designed to be real, functional, beautiful boats as a first priority but ease-of-construction and build method is very much a part of the design process. There are a few ways the hulls are constructed depending on the design and they all utilize plywood-epoxy and what I call “Tab-n-Lock”:

Screw-and-glue, wood chine construction (the focus of this post)

Glued plywood lapstrake (will cover later)

Tack-and-tape seam construction (will also cover later)

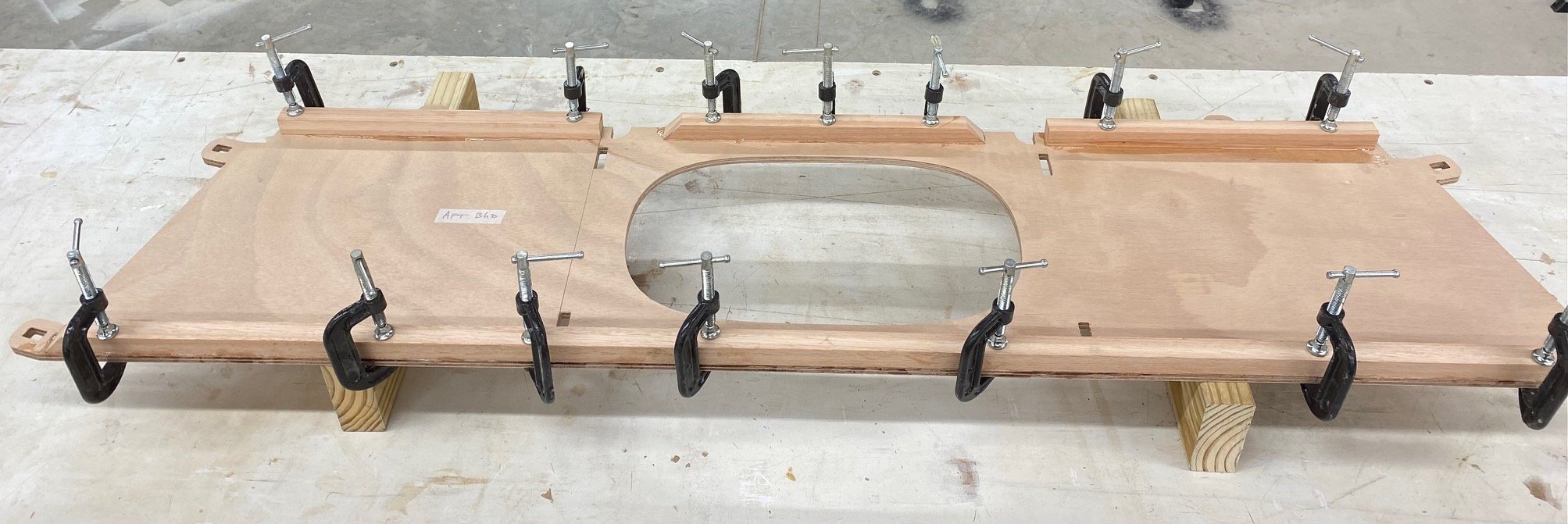

The “easy-to-build” line up of boats all utilize the first method in the list above - boats like the Echo Bay Dory Skiff and Compass Skiff. They are excellent beginner boats because they do not require a strongback and have few parts to assemble. They also offer great lessons in real boatbuilding skills: bending wood, planing a bevel, predrilling and driving for screws, using clamps and other basic tools, and using epoxy and wood to make good, strong joints. In just a few days of working you can have the hull built without the mess of stitch-and-glue construction.

One anecdote sums up why I do not believe in the perceived superiority of Stitch-and-glue construction. At WoodenBoat School in beautiful Brooklin, Maine where I teach in the summers, I was teaching a build-your-own Echo Bay class. While my students were enjoying making long, cedar shavings with their hand tools, planing down the chines to receive the bottom, someone from the stitch-and-glue class came over, hands gloved covered in dripping epoxy and fiberglass, and said, “oh, cool, you guys get to use real tools in this class!”. One of my students noted how the stitch-and-glue guys already had a hull put together day 1 while they were still making parts (which they were enjoying, but they were clearly noticing that the other class already had hulls wired together). At the end of the week though, both classes had boats built, and our easy-to-build, tab-n-lock, screw-and-glue boats were further along (like they were totally done) and, as a couple students noticed, looking cleaner.

Next blog post we’ll talk about glued lapstrake and tack-and-tape methods to further illustrate our approach to boat kit construction.